What Is The Reason For The Brittleness Of Plastic Pail Mould?

Body

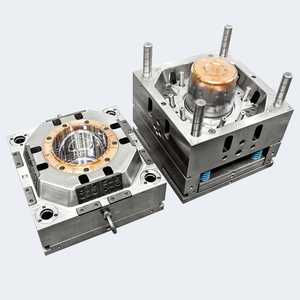

Diversified sealed Plastic Pail Mould can realize multi-category selection and clarification. Therefore, we will follow our selection characteristics and purchase suitable products. The plastic bucket is made of brand new materials. No illegal materials are added during the procurement and processing process, which is suitable for food processing. Chemical smoothness ensures cargo transportation and doubles the loading and unloading of chemicals. The barrel is beautiful: high-tech strictly controls the appearance change, which suits our beauty. Plastic buckets can be conveniently packed and cleaned for food. Its reasonable manufacturing and professional brand are still used in the handling, distribution, placement and smooth manufacturing process acquired by the factory. Plastic drums are used for packaging and loading Bucket mould many selected goods. They can be manufactured in accordance with the manufacturer's instructions.

In the process of use, plastic barrels sometimes become brittle. Fragile plastic buckets will only be damaged, which is not conducive to long-term use. The brittleness of plastic barrels is closely related to the selection of production molds, raw materials, production machinery and production processes. Plastic barrel manufacturers introduced how to avoid the embrittlement of plastic barrels from the production process.

1. The temperature of the cylinder and nozzle is too low and needs to be adjusted. If the material is simply degraded, the temperature of the cylinder and nozzle should be increased.

2. Reduce the back pressure and rotation speed of the screw preform to loosen the material and reduce the deterioration of the plastic due to shearing overheating.

3. The mold temperature is too high and it is difficult to demold. The mold temperature is low, the plastic is cooled prematurely, and the fusion joint is poorly fused and easy to crack. It is especially suitable for high melting point plastics such as polycarbonate.

4. The plastic barrel core should have an appropriate demoulding angle. When the core is difficult to demold, the temperature of the cavity should be increased and the cooling time should be shortened. When the cavity is difficult to separate, the temperature of the cavity should be lowered and the cooling time should be prolonged.

We are a professional molding company, sell different design of mold, 20L Bucket Mould is one of them,welcome to visit our website.

Comments