Flooded Evaporators And Dry Evaporators

الجسم

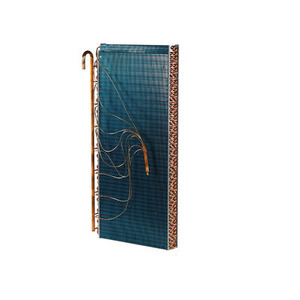

The evaporator uses the principle that liquid low-temperature refrigerant is easy to evaporate under low pressure, and achieves the purpose of lowering the indoor temperature by absorbing the heat in the indoor environment. The evaporator is mainly composed of a heating chamber and an evaporation chamber. The heating chamber provides the liquid with the heat required for evaporation, which promotes the boiling and vaporization of the liquid; the evaporation chamber completely separates the gas-liquid two phases.

The evaporator is located between the throttle valve and the return air main pipe of the refrigerator or between the liquid supply and return air pipes connected to the vapor-liquid separation equipment, and is installed in the cold room or place where cooling and freezing are required.

Evaporators can be divided into flooded type, falling film type, and direct expansion type.

Advantages of flooded evaporator: compact structure, convenient operation, and management, high heat transfer coefficient.

Disadvantages of flooded evaporators: when the refrigerant is fresh water, ice may form in the tube, causing the tube to burst, the temperature at the bottom of the liquid rises, the heat transfer temperature difference is reduced, and it is difficult to return oil to the refrigerant that is miscible with lubricating oil, and the refrigerant is charged. When the filling volume is large and it is used on ships, the liquid level swing is likely to cause a cylinder flushing accident.

Advantages of dry evaporators: guarantee to bring lubricating oil back to the compressor, less refrigerant charge (1/3), no freezing when the evaporation temperature is around 0°C, and a thermal expansion valve can be used to supply liquid, which is simpler than using a float valve, reliable.

Disadvantages of dry evaporators: gas-liquid stratification occurs in the end cover, which affects the uniform distribution of the next process and leaks on the waterside.

For more product-related information, check out the custom evaporator coil manufacturer!

تعليقات