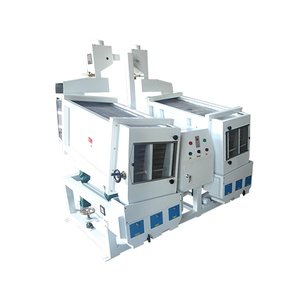

Application of Gravity Rough Paddy Separator

Body

On the one hand, the gravity grain rough Paddy Separator(LIANGGONG) produced in the domestic market are mostly imitation Japanese products and their improved products, mainly designed and produced for rice processing and grain screening. Currently, they are widely used and have good effects, especially in the rice milling process. The addition of the grain rough separator can greatly increase the rice milling rate and increase the economic benefit. On the other hand, gravity grain rough separators are used less in the storage of raw grain, especially in rice storage operations. According to the feedback from the companies that have used the machine for rice storage, in practical applications, the design concept is not directed at the original grain storage operation, and many problems arise that result in poor application or difficulty in continuing to use.

Rice is one of the main food crops in China, with a long history of planting and a large planting area. At present, the domestic storage of rice is mainly based on rice. Rice (including brown rice) is a living organism. During storage, not only does it have slow metabolism, but also changes with storage conditions and storage time. The quality is gradually changing. In the process of harvesting, threshing, loading and unloading and transportation, the rice is subjected to mechanical pressing or impacting to cause the grain to be shelled to form extragranular brown rice. The brown rice outside the valley loses the protection of the hull, the cortex and the embryo are directly exposed. On the one hand, the rich lipids in the cortex are more susceptible to oxidative rancidity during storage. On the other hand, the brown rice outside the valley is more susceptible to microorganisms and pests. Influence, so brown rice is more prone to quality degradation than rice. The high content of brown rice outside the valley is not conducive to the safe storage of food.

Click Paddy Husker to learn about more information.

Comments