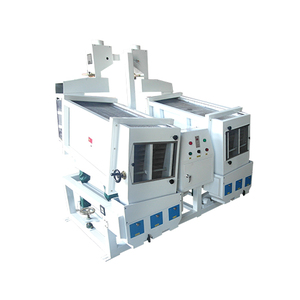

Difficult Application of Paddy Separator

الجسم

1. Low flow rate and high energy consumption In the processing of rice and grain screening, the flow demand of the Paddy Separator(LIANGGONG) is generally about 10t per hour, and several groups of machines may be used at the same time. The MGCZ machine can fully meet the demand. However, in the operation of rice storage, since the current flow rate of grain conveying equipment is generally 50t to 80t per hour, the flow rate of the paddy separator is obviously unable to meet the demand of rice storage. For example, if a bulk truck with 40t rice is used for unloading, it would take less than 1 hour to be unloaded. However, after adding the paddy separator, the theoretical unloading time will be extended to 4 hours. decrease productivity.

2. When a single group of machinery can not meet the actual storage requirements, it is necessary to run multiple sets of machinery at the same time when entering the warehouse, or to add waste removal equipment due to the need to remove impurities from the storage of rice, or to encounter the need for replenishment operations. At the time, the energy required for storage will increase significantly. And the simultaneous operation of multiple sets of machinery is bound to put forward higher requirements for electromechanical safety, site arrangement, and operational capability, which brings many hidden dangers.

3. The vibration is large, and the tilting reciprocating vibration of the paddy separator will cause the body to vibrate, shift and jump. In the rice processing and grain screening production, the four-legged fixing screw is used in the indoor environment. To avoid displacement and runout caused by severe vibration, and this fixation is permanent and generally does not move easily. In the rice warehousing operation, it is necessary to constantly adjust and move the mechanical position to meet the warehousing and replenishment requirements. However, the fixed method of the paddy separator design cannot meet this requirement, so each time the machine is moved, not only is it difficult to move, it is time-consuming and labor-intensive, and the operation is inconvenient, and the ground is continuously damaged by the use of the expansion screw.

Click Paddy Husker to learn about more information.

تعليقات