Blog Information

- Posted By : xinjia shaoxing

- Posted On : Mar 16, 2021

- Views : 314

- Category : General

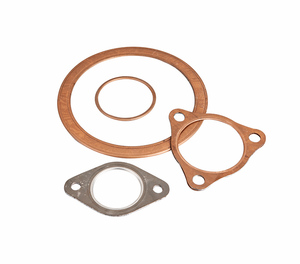

- Description : The gasket with a metal sleeve is made of a soft material (FM, PTFE, graphite, etc.), part or all of which is coated with a malleable metal foil.

Overview

The gasket with a metal sleeve is made of a soft material (FM, PTFE, graphite, etc.), part or all of which is coated with a malleable metal foil. The material quality of the metal sheath gasket must be selected according to the working pressure and the fluid in contact with it. Due to its easy-to-understand structure and light, under pressure and high temperature, metal is more fully displayed than metal.

The metal-clad gasket can be manufactured with one or more ribs arranged in different configurations. Metal Jacketed Gaskets Manufacturers' metal jacketed gaskets are based on standards such as ASME 16.20 or according to specific customer specifications. The most commonly used materials for making metal-plastic joints are metal materials: copper, aluminum, AISI 304, 316L, 321, soft iron, and filler materials: mineral fiber or graphite.

Size and form:

The metal-coated gaskets are manufactured in the most diverse round, oval, rectangular, square, and diamond forms, Spiral Wound Gaskets For Sale. These plates have however no size limitation depending on the width limitation of commercial materials, sometimes it is necessary to use welding which performs the following welding procedure. The standard thickness is 3.2 mm. Although it depends on the use, it can be higher or lower.