Unlock the Secrets of Variable Frequency Drives: Transform Your Industrial Efficiency Today!

In the heart of modern industrial operations lies a technology that has revolutionized how machines function: variable frequency drives (VFDs). These devices play a crucial role in optimizing industrial efficiency by controlling the speed and torque of electric motors, which are fundamental to various processes. As industries face increasing pressure to enhance performance and reduce energy consumption, understanding the significance of VFDs becomes paramount. This article will delve into the intricate workings of variable frequency drives, exploring their functions, benefits, and diverse applications in industrial settings. By the end, you will understand how VFDs can transform your operations and contribute to a more sustainable future.

Understanding Variable Frequency Drives

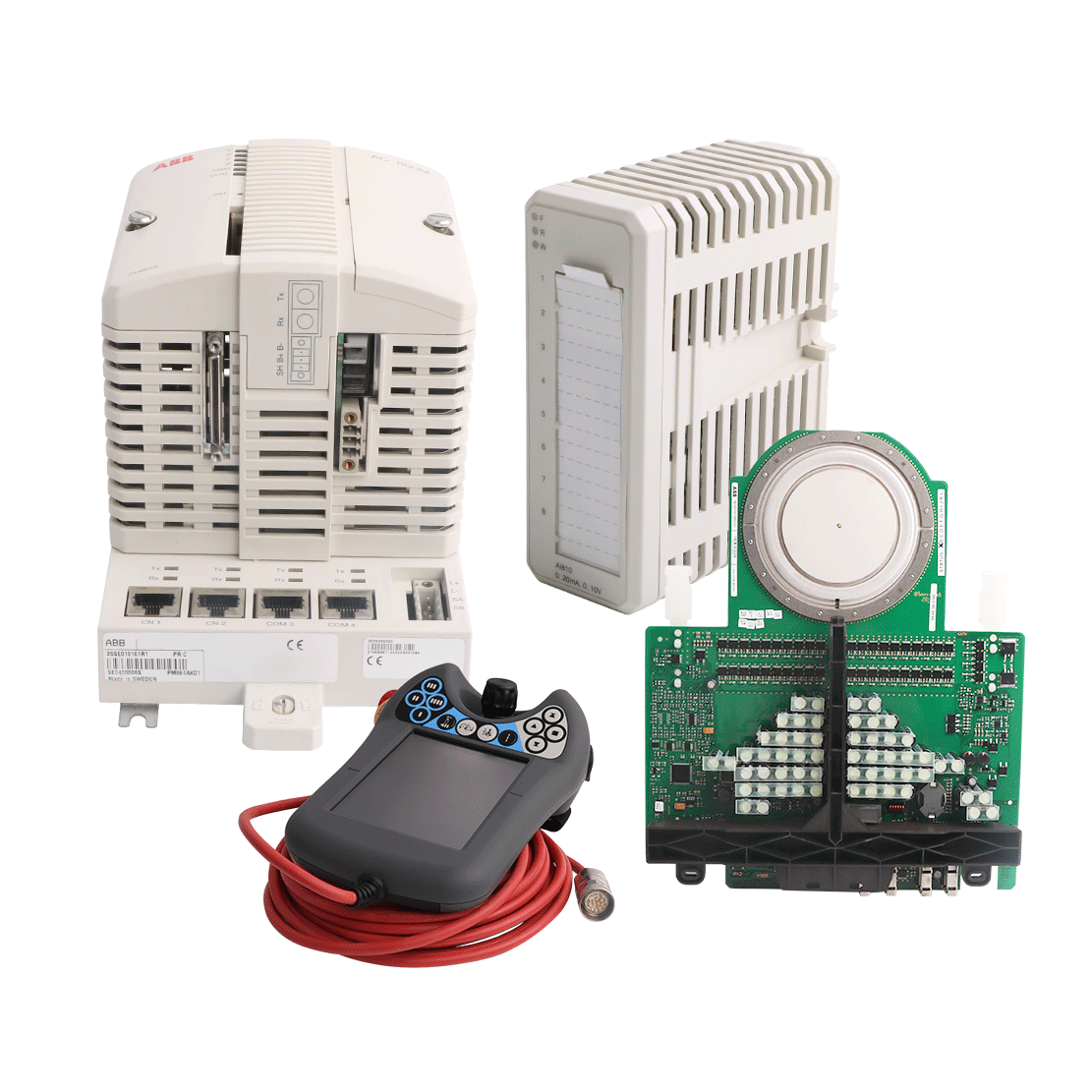

Variable frequency drives are sophisticated electronic devices designed to control the speed and torque of electric motors by varying the frequency and voltage of the power supplied to the motor. The basic components of a VFD include a rectifier, a DC bus, and an inverter. The rectifier converts incoming AC power into DC power, which is then stored in the DC bus. The inverter converts this DC power back into AC power at the desired frequency and voltage. This process allows for precise control over motor speed and torque, enabling more efficient operation. My friend, a maintenance engineer, shared how implementing VFDs in their facility not only improved energy management but also reduced the unnecessary wear and tear on motors, prolonging their lifespan significantly. This is especially beneficial in industries where motors are subjected to variable load conditions.

Key Functions of Variable Frequency Drives

The primary functions of variable frequency drives center around speed control, torque control, and energy savings. Speed control allows operators to adjust the motor speed to match the requirements of the application, leading to smoother operations and enhanced process efficiency. Torque control ensures that the motor delivers the necessary torque at varying speeds, which is critical for applications such as conveyor systems and fans. Additionally, VFDs contribute to energy savings by reducing the motor speed when full power is not required, which can lead to significant reductions in energy consumption. A colleague of mine in the automotive industry reported a 30% decrease in energy costs after integrating VFDs into their assembly line processes, illustrating the economic benefits of this technology.

Benefits of Implementing VFDs in Industry

Implementing variable frequency drives in industrial settings offers numerous benefits that extend beyond energy efficiency. One of the most significant advantages is the reduction in wear and tear on equipment, as VFDs allow for gradual acceleration and deceleration of motors, which minimizes mechanical stress. This leads to longer equipment lifespans and reduced maintenance costs. Improved process control is another critical benefit, as VFDs enable precise adjustments to motor operations, which can enhance the quality of products and reduce waste. Economically, the return on investment (ROI) associated with VFD implementation can be substantial. Companies often experience lower utility bills and decreased maintenance expenses, which can offset the initial costs of installation within a short period. My friend’s factory, after switching to VFDs, saw their payback period reduced to just under two years, a testament to how this technology can bolster financial performance.

Applications of Variable Frequency Drives

Variable frequency drives find applications across a broad spectrum of industries, showcasing their versatility and effectiveness. In manufacturing, VFDs are commonly used to control motors in conveyor systems, pumps, and fans, leading to increased production efficiency. In HVAC systems, they help regulate air flow and temperature, contributing to energy conservation and better indoor air quality. Water treatment plants utilize VFDs to manage the speed of pumps, ensuring optimal flow rates while minimizing energy usage. A notable case study from a municipal water treatment facility demonstrated a reduction in energy consumption by over 20% after the installation of VFDs, highlighting their impact on sustainability. From food processing to mining, the applications of VFDs are diverse, proving their essential role in modern industrial operations.

Maximizing Operational Efficiency with VFD Technology

In conclusion, variable frequency drives are pivotal in enhancing industrial efficiency through their advanced control over motor operations. Their functions—speed control, torque management, and energy savings—offer numerous benefits, including reduced equipment wear, improved process control, and significant cost savings. As industries continue to seek sustainable solutions and strive for operational excellence, embracing VFD technology becomes increasingly important. By considering how VFDs can be integrated into your operations, you stand to not only improve your bottom line but also contribute to a more sustainable and energy-efficient future.