Quanzhou Howfun IMP & EXP Trading Co., Ltd. » Notes » How to cut steel wire rope?

-

How to cut steel wire rope?

Why Proper Cutting Matters

A proper cut preserves strength. It prevents fraying, bird-caging, and unsafe ends. Poor cuts cause injuries, waste material, and failed rigging. When you cut steel wire rope cleanly, you can attach fittings securely.

Safety Precautions

Wear gloves to protect hands. Use safety glasses to shield eyes. Use long sleeves and sturdy boots. Secure your work area — remove loose items. Always cut with tools in good condition. A slipping cable end can be dangerous.

Preparation Before Cutting

First inspect the steel wire rope. Check for broken strands or corrosion. Mark the exact cut point with tape or marker. Wrap tape tightly around the rope near cut point to hold strands. Secure the rope in a vise or clamp to prevent spinning. Double-check length measurements before cutting.

Table: Common Rope Descriptions

Rope Type Strand / Core Common Use 6×19 6 strands, 19 wires each General lifting 7×7 7 strands of 7 wires Light rigging, cables 6×36 6 strands with many fine wires Flexible applications IWRC core Independent wire rope core High strength, less crush

Selecting the Right Tool

The tool you pick depends on rope size and material. For small ropes, hand shear cutters work. For medium cables, ratchet or manual wire rope cutters help. For heavy ropes, hydraulic cutters or power tools are best. Avoid using bolt cutters or pliers—they tend to crush the rope instead of cleanly shearing it.

Examples of tools:

-

Manual shear wire rope cutter

-

Ratchet cutter

-

Hydraulic cutter

-

Chop saw with abrasive blade

Always check the cutter’s capacity to match the diameter of steel wire rope you are cutting.

Table: Tool vs Rope Size

Tool Type Max Diameter Best Use Case Manual shear ~½ inch Light cable work Ratchet cutter ~1 inch Medium rigs Hydraulic cutter 2″+ Heavy rope cutting Abrasive chop saw any Fast shop cuts (use safety)

Cutting Techniques & Best Practices

Align the cutter with the mark. Apply steady pressure rather than rush. Let the tool do the work. If using a saw, use a fine blade and go slow. Avoid overheating the wire. Keep strands together by taping both sides before cutting. Make one smooth cut, avoid sawing back and forth too much. Always keep the cutter jaws well maintained and sharp.

Table: Techniques & Effects

Technique Effect Tip Pre-tape wrap Prevent fraying Use masking or steel wire One firm cut Clean end Avoid multiple strokes Steady pressure Less damage Let tool work Cool wire after cut Preserve strength Use coolant or water

Finishing the Cut Ends

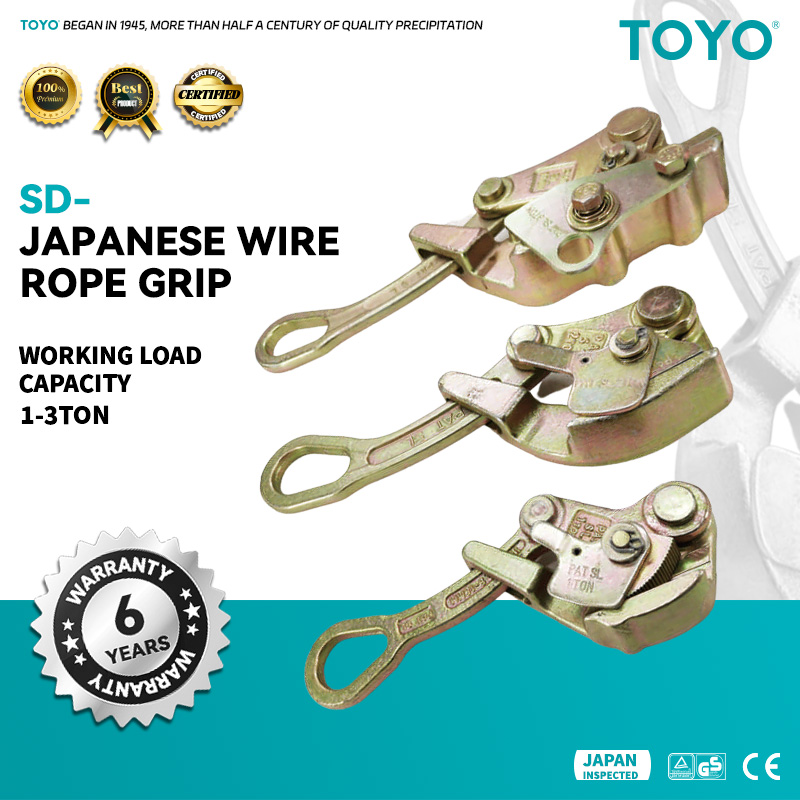

After cutting, wrap the end immediately with tape or wire to avoid splaying. You can use a ferrule or swage sleeve to clamp the end. Use heat shrink tubing for light use. For heavy duty use, insert fittings or wire rope grips. Make sure the end is smooth and round before adding hardware.

Repairing Damage & Recuts

If your cut end has frayed, shorten the rope and cut again in a better spot. Always reseize the rope before cutting. Avoid using already damaged lengths for critical loads.

Real-World Examples & Common Pitfalls

In marine use, cutting cables for winches or rigging needs clean ends or you risk fraying. In construction cranes, a flawed cut can degrade the load capacity. Some operators mistakenly use bolt cutters, resulting in crushed cores. Another mistake: leaving the rope free to rotate during the cut — that causes twist and rough ends.

Summary

Cutting steel wire rope requires planning, the right tools, and care. You must secure the rope, mark the cut, wrap strands, apply a proper tool, finish the end, and avoid damage. By following the steps above and selecting cutters suited to the rope size, you can get clean, safe cuts every time.

-

-