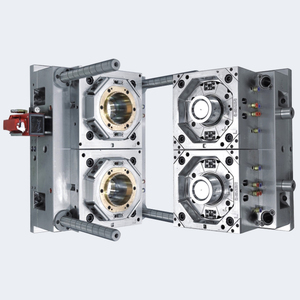

What Are the Reasons for the Cooling Rate of Plastic Pail Mould?

Corps

In the injection molding process of Plastic Pail Mould, how to determine the cooling time not only affects the quality of the product, but also affects the cost of the product. For production and products, the first consideration is to transfer the necessary heat from the plastic melt injected into the mold cavity to the solid so that it can be taken out of the mold without deformation. Therefore, the correct estimation of the cooling time has become the main process parameter that should be determined first in the two-color mold injection process.

Reasons that affect the cooling rate of the two-color mold:

1. Mold material and its cooling method.Plastic furniture mould When it comes to mold material, including mold core, cavity material and template material, it has a great influence on the cooling rate. The higher the heat transfer coefficient of the two-color mold material, the better the heat transfer from the plastic per unit time, and the shorter the cooling time.

2. The design of plastic products is mainly the wall thickness of the plastic products. The greater the thickness of the two-color mold product, the longer the cooling time.

3. Cooling water pipe configuration. The closer the cooling water pipe is to the cavity, the larger the pipe diameter and the larger the number, the better the cooling effect. The shorter the cooling time, the shorter the flow of the cooling liquid. The larger the flow of cooling water, the better the effect of cooling water through convection heat exchange.

Fourth, the choice of plastic, which refers to the measurement of the rate at which the plastic conducts heat from the hot ground; the higher the heat transfer coefficient of the plastic, the better the heat transfer effect, or the lower the specific heat of the plastic, the temperature is easy to change, so the heat is easy to radiate , The better the thermal conductivity, the shorter the cooling time is required.

5.The nature of the coolant, the viscosity and heat transfer coefficient of the coolant also affect the heat transfer effect of the two-color mold product injection molding. The lower the viscosity of the coolant, the higher the heat transfer coefficient, the lower the temperature, and the better the cooling effect.

We are a professional molding company, sell different design of mold, Paint Pail Mould is one of them,welcome to visit our website.

commentaires