Transform Your Factory: Discover the Power of Industrial-Strength Retrofit LED Fixtures!

In today’s fast-paced industrial landscape, lighting plays a crucial role in ensuring operational efficiency and worker safety. Enter industrial-strength retrofit LED fixtures—designed specifically to meet the rigorous demands of factory environments. These fixtures not only provide superior lighting quality but also offer significant energy savings and a longer lifespan compared to traditional lighting options. Upgrading to LED technology can transform a factory floor, enhancing visibility and reducing overhead costs. By embracing this modern lighting solution, manufacturers can foster a safer and more productive work environment, paving the way for better performance and sustainability.

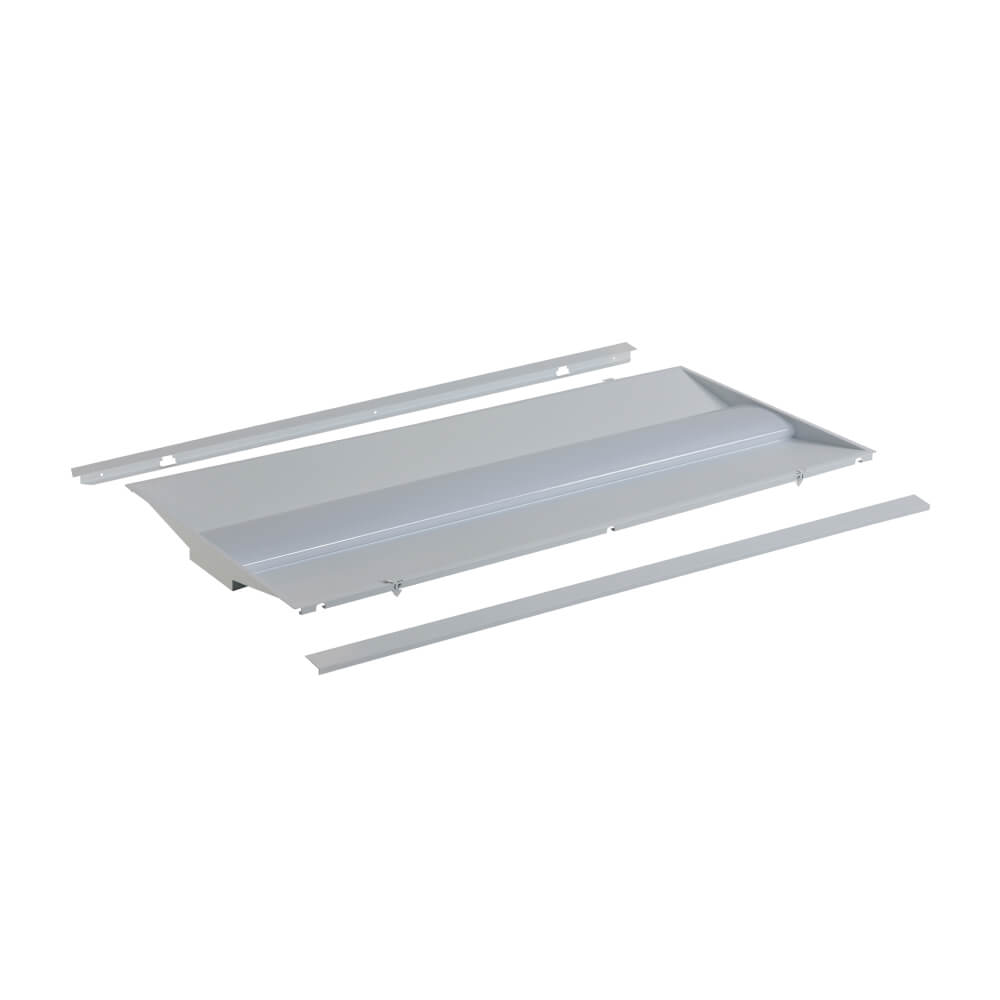

Understanding Industrial-Strength Retrofit LED Fixtures

Industrial-strength retrofit LED fixtures are specialized lighting solutions designed to be installed in existing light fixtures without requiring a complete overhaul of the current lighting system. These fixtures are built to withstand the unique challenges of factory settings, including exposure to dust, moisture, and vibrations. Typically, they feature robust housing materials, higher IP ratings for water and dust resistance, and are capable of delivering high lumen output for optimal brightness. Furthermore, energy efficiency is at the forefront of their design, allowing factories to reduce energy consumption significantly while still achieving superior illumination. The durability and efficiency of these fixtures make them a reliable choice for any industrial application.

Applications in Factory Settings

Retrofit LED fixtures have a wide range of applications across various factory settings. For instance, they can be used to illuminate assembly lines, ensuring that workers have adequate light to perform detailed tasks safely and accurately. In warehouses, these fixtures can enhance visibility in storage areas, preventing accidents and improving the efficiency of picking and packing operations. Workstations, often featuring intricate machinery, greatly benefit from well-distributed lighting, which allows for a safer working environment and increases productivity. By ensuring that every corner of a factory is well-lit, employers not only comply with safety regulations but also enhance the overall morale and performance of their workforce.

Implementation Considerations

When considering the implementation of retrofit LED fixtures in a factory, several critical factors need to be taken into account. First, assessing the existing lighting infrastructure is essential to determine compatibility with the new fixtures. Factories often have diverse lighting setups, and understanding the specific requirements for each area can help in selecting the right retrofit options. Additionally, evaluating the potential for energy savings is crucial; many facilities overlook the cumulative impact of upgrading to LED, which can lead to significant reductions in utility costs. Proper planning ensures that the transition is smooth and that the new fixtures meet the operational needs of the factory.

Installation Process

The installation of retrofit LED fixtures typically involves several key steps. Initially, thorough planning is necessary, including mapping out the layout of the existing lighting system and identifying areas that require enhanced illumination. Once planning is complete, professional installation is recommended to ensure safety and compliance with local regulations. This step includes the removal of old fixtures, installation of the new retrofit LEDs, and testing to confirm functionality. A meticulous installation process not only minimizes disruptions to daily operations but also guarantees that the lighting systems function optimally.

Benefits of Upgrading to LED Fixtures

The advantages of switching to industrial-strength retrofit LED fixtures extend beyond mere illumination. One of the most compelling benefits is the reduction in energy costs, as LEDs consume significantly less power compared to traditional lighting options. Additionally, the longevity of LED fixtures means less frequent replacements, leading to reduced maintenance costs and downtime. Safety is another critical aspect; improved visibility directly correlates with fewer workplace accidents. Moreover, as businesses increasingly prioritize sustainability, the lower carbon footprint of LED technology contributes positively to corporate social responsibility goals. Upgrading to LED fixtures is not just a smart financial decision; it’s an investment in a safer, more efficient workplace.

Maximizing Efficiency and Safety with LED Upgrades

In conclusion, industrial-strength retrofit LED fixtures represent a transformative opportunity for factories looking to enhance their lighting systems. The combination of energy efficiency, durability, and improved workplace safety makes them an attractive choice for modern manufacturing environments. As industries continue to evolve, investing in high-quality lighting solutions will not only boost productivity but also contribute to a sustainable future. Factory owners and managers are encouraged to consider this upgrade as a strategic move towards greater efficiency and safety in their operations.

Comments