Unleash the Brilliance: Discover the Hidden Advantages of Cutting-Edge Industrial LED Lighting!

In today's fast-paced industrial landscape, the adoption of advanced lighting solutions is becoming increasingly important. Industrial LED lighting solutions are at the forefront of this evolution, offering a sustainable and efficient alternative to traditional lighting methods. Unlike incandescent or fluorescent bulbs, LEDs consume significantly less energy, produce less heat, and boast a longer lifespan, making them a smart choice for industries aiming to reduce costs and improve productivity. As we delve deeper into this article, we will explore the various types of industrial LED lighting, their unique benefits, and the cutting-edge technologies that make them indispensable in modern workplaces. By understanding these aspects, industries can harness the full potential of LED lighting to enhance their operational environments.

Understanding Industrial LED Lighting Solutions

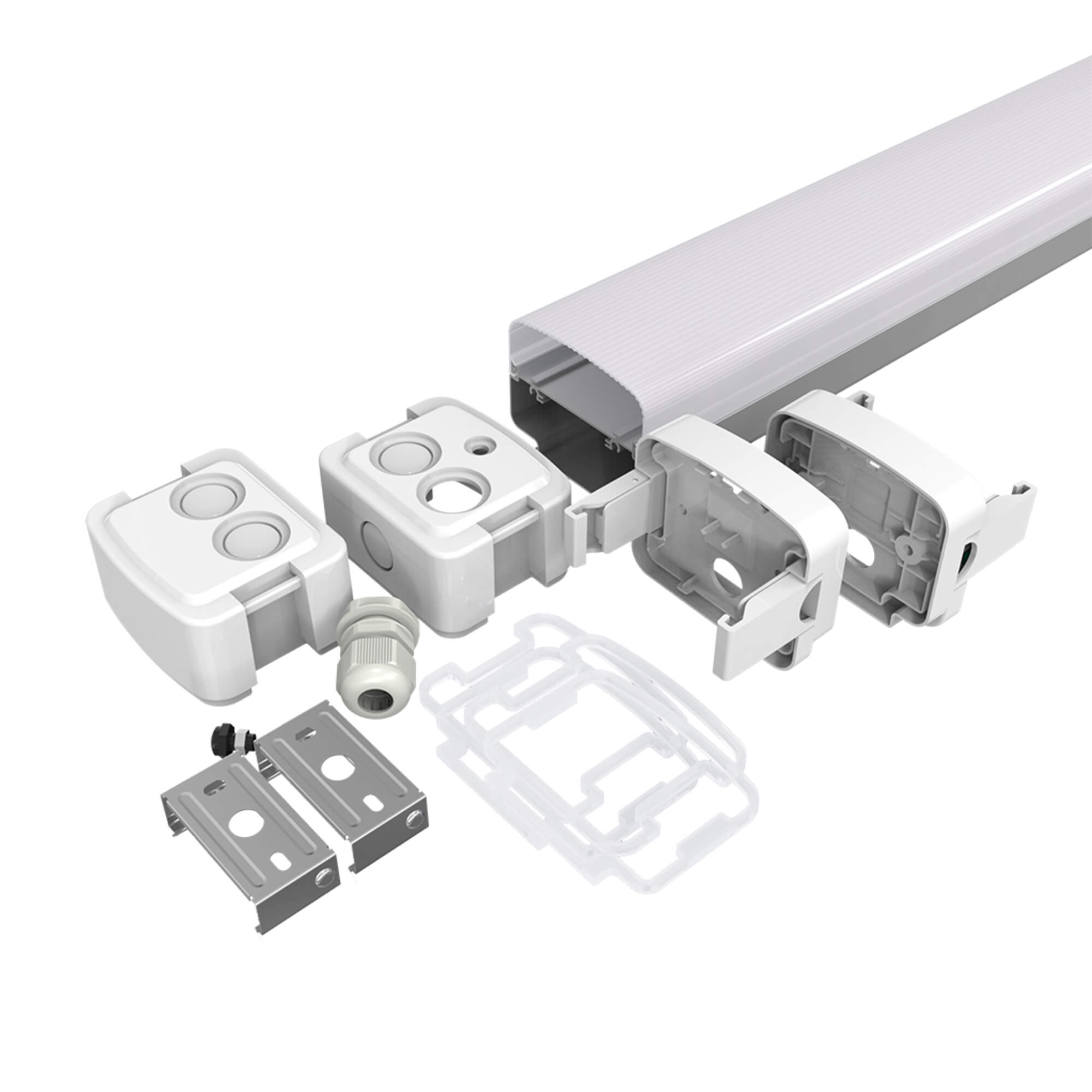

Industrial LED lighting solutions are specialized lighting systems designed for various industrial applications, such as warehouses, manufacturing plants, and distribution centers. These solutions typically consist of LED light sources, advanced optics, and robust housing that can withstand harsh conditions. The primary feature that sets LED lighting apart from traditional options is its energy efficiency. LEDs convert a higher percentage of energy into visible light, which means more brightness with less power consumption. Moreover, they are made from durable materials that resist shock and vibration, making them ideal for demanding environments. This durability, combined with their versatility in design and output, allows for tailored lighting solutions that meet specific industrial needs, ensuring optimal visibility and safety in the workplace.

Types of Industrial LED Lighting Solutions

There are several types of industrial LED lighting solutions, each tailored for specific applications. High bay lights, for instance, are designed for spaces with ceilings higher than 15 feet, commonly found in warehouses and manufacturing facilities. They provide intense illumination to cover large areas effectively. On the other hand, low bay lights are suitable for lower ceiling heights and are often used in retail spaces and assembly lines. Floodlights are another essential type; they are used for outdoor applications, illuminating large areas such as construction sites and parking lots. Finally, task lighting focuses on specific work areas, providing concentrated light for precision tasks, such as assembly work or quality inspections. Each type is engineered to address the unique lighting requirements of different industrial settings, ensuring that every area is well-lit and operationally efficient.

Benefits of Industrial LED Lighting

The adoption of industrial LED lighting solutions comes with numerous benefits that significantly impact operational efficiency. One of the most compelling advantages is energy efficiency; LEDs consume up to 75% less energy than traditional bulbs, leading to substantial cost savings over time. Additionally, these lighting solutions have a lifespan of up to 50,000 hours or more, reducing the need for frequent replacements and lowering maintenance costs. Improved safety and visibility are other crucial benefits; brighter and more evenly distributed light minimizes shadows and dark spots, reducing the risk of accidents in the workplace. Furthermore, the cooler operation of LED lights mitigates the risk of heat-related accidents, creating a safer working environment. Overall, the transition to industrial LED lighting not only enhances productivity but also contributes to a more sustainable future.

Technologies Behind Industrial LED Lighting

The advanced technologies behind industrial LED lighting are a driving force behind their effectiveness and efficiency. Smart lighting systems, for instance, enable real-time monitoring and control of lighting environments, allowing facilities to adapt lighting levels based on occupancy and natural light conditions. This capability not only conserves energy but also enhances the comfort of the workspace. Dimming capabilities further add to the flexibility of LED lighting, allowing users to adjust brightness based on specific tasks or times of day. Moreover, the integration with the Internet of Things (IoT) facilitates seamless connectivity and data exchange between lighting systems and other building management systems. This interconnectedness can lead to improved operational insights and energy management, demonstrating how technology is revolutionizing the industrial lighting landscape.

Transforming Industrial Lighting for a Sustainable Future

In summary, the benefits of industrial LED lighting solutions are clear. From energy efficiency and longevity to advanced technologies that enhance functionality, these innovative lighting options are transforming the way industries operate. As companies continue to seek ways to improve productivity and reduce costs, the transition to LED lighting presents a compelling opportunity. By embracing these cutting-edge solutions, industries can not only enhance their operational environments but also contribute to a more sustainable future. For anyone considering an upgrade, the long-term advantages of industrial LED lighting solutions are undeniable, paving the way for a brighter, more efficient industrial landscape.

commentaires