Unlock the Secrets to Sourcing Retrofit Kits from China’s Hidden Gems!

In today's fast-paced industrial landscape, the demand for retrofit kits is higher than ever. These kits play a crucial role in upgrading existing systems across various sectors, including automotive, electronics, and construction. As industries strive for efficiency and sustainability, the ability to implement retrofitting solutions becomes vital. China has emerged as a significant player in this market, offering a plethora of options for businesses looking to enhance their operations. However, it's not just the well-known suppliers that hold the key to quality products; lesser-known suppliers often provide innovative solutions at competitive prices. In this article, we will explore the benefits of sourcing retrofit kits from these hidden gems in China, ensuring that you make informed decisions for your projects.

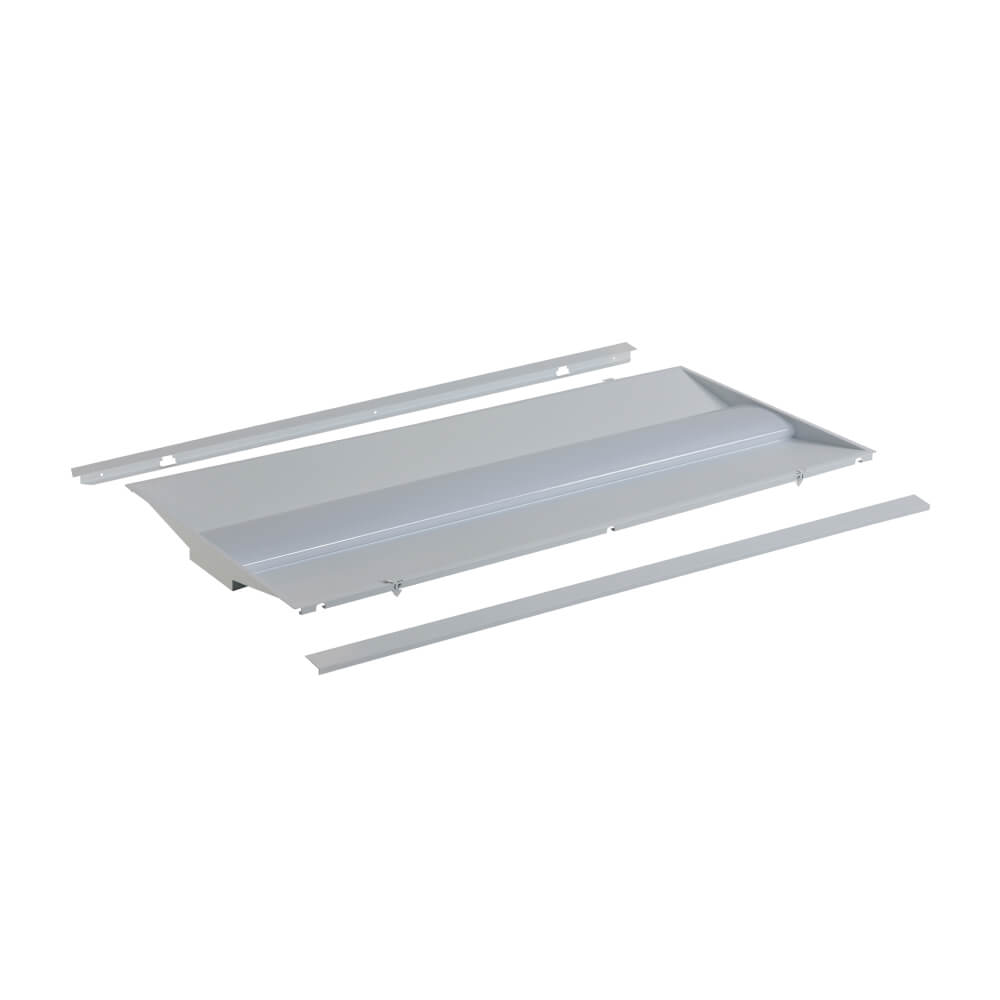

Understanding Retrofit Kits and Their Applications

Retrofit kits are designed to upgrade or enhance existing systems without the need for complete replacements. They find applications across various sectors, including automotive, where they can improve vehicle performance and emissions. In electronics, retrofit kits can modernize outdated technology, extending its lifespan and functionality. In construction, these kits can help buildings meet new energy efficiency standards or adapt to changing regulations. Understanding the specific requirements of your project is crucial, as the quality of the retrofit kits directly impacts the project's success. For instance, a friend of mine in the construction industry once faced significant challenges due to poor-quality kits sourced from a supplier. This experience highlighted the importance of sourcing quality kits tailored to specific applications.

The Advantages of Sourcing from China

Sourcing retrofit kits from China comes with a myriad of advantages. Cost-effectiveness is often the most significant benefit, as manufacturers in China frequently offer lower prices due to reduced labor costs and economies of scale. Additionally, the variety of products available is unmatched; you can find everything from basic kits to highly specialized solutions. Innovation is another key factor; many Chinese suppliers are at the forefront of technological advancements, providing products that can enhance efficiency and performance. Moreover, exploring lesser-known suppliers can lead to discovering unique offerings that larger companies may overlook. A colleague once shared how they found a small supplier in China that provided a groundbreaking retrofit kit for their manufacturing equipment, resulting in substantial cost savings and improved efficiency.

How to Identify Hidden Gem Suppliers

Finding lesser-known suppliers in China requires a strategic approach. Start by utilizing online platforms like trade directories and B2B marketplaces, where you can filter suppliers based on product categories and reviews. Attending trade shows is another effective method; these events provide direct access to manufacturers and allow for personal interaction, which can be invaluable in building relationships. Additionally, leveraging local networks and industry contacts can lead you to suppliers that may not be widely advertised. A friend who operates in the electronics sector often emphasizes the importance of word-of-mouth recommendations, which have led him to discover reliable suppliers that others might miss. Always remember that thorough research and due diligence are critical in this process.

Evaluating Supplier Credibility and Product Quality

Once you've identified potential suppliers, it's essential to evaluate their credibility and the quality of their products. Start by checking online reviews and testimonials from previous clients. Certifications and compliance with industry standards can also offer insights into a supplier's reliability. Additionally, it's wise to request samples of the retrofit kits before making a larger investment; this allows you to assess the quality firsthand. A mentor of mine shared their experience of receiving subpar products from a supplier due to inadequate quality checks, reinforcing the necessity of conducting thorough evaluations. Furthermore, consider past projects the supplier has completed, as these can be indicative of their ability to meet your specific needs.

Navigating Negotiations and Shipping Logistics

Negotiating terms with suppliers can significantly impact your overall sourcing experience. It's crucial to communicate your requirements clearly and be open to discussions about pricing, lead times, and payment terms. Understanding shipping logistics is equally important; familiarize yourself with customs regulations that may affect your shipment. To ensure timely delivery, consider working with freight forwarders who can navigate the complexities of international shipping. A friend who recently sourced retrofit kits from China recommended establishing a buffer period for delivery, as unexpected delays can occur. This proactive approach can save you from potential project setbacks.

Maximizing Opportunities through Strategic Sourcing

Sourcing retrofit kits from China's hidden gems can unlock numerous opportunities for your projects. By understanding the applications of retrofit kits, recognizing the advantages of sourcing from China, and employing effective strategies to identify and evaluate suppliers, you can enhance your sourcing experience. As the market continues to evolve, exploring lesser-known suppliers may lead you to innovative solutions that can set your business apart. Take action today and start your journey towards discovering the exceptional value that awaits you in China!

Comments