Unlock the Secrets to Choosing the Best ABB VFD Suppliers!

In the ever-evolving landscape of industrial automation, Variable Frequency Drives (VFDs) play a crucial role in optimizing equipment performance and enhancing energy efficiency. Among the various options available, ABB VFDs stand out due to their advanced technology and reliable performance. Selecting the right supplier for these drives is equally important, as it can significantly impact your operational efficiency and overall project success. This article will guide you through the evaluation of suppliers, focusing on key criteria that will help you make an informed choice when purchasing ABB VFDs.

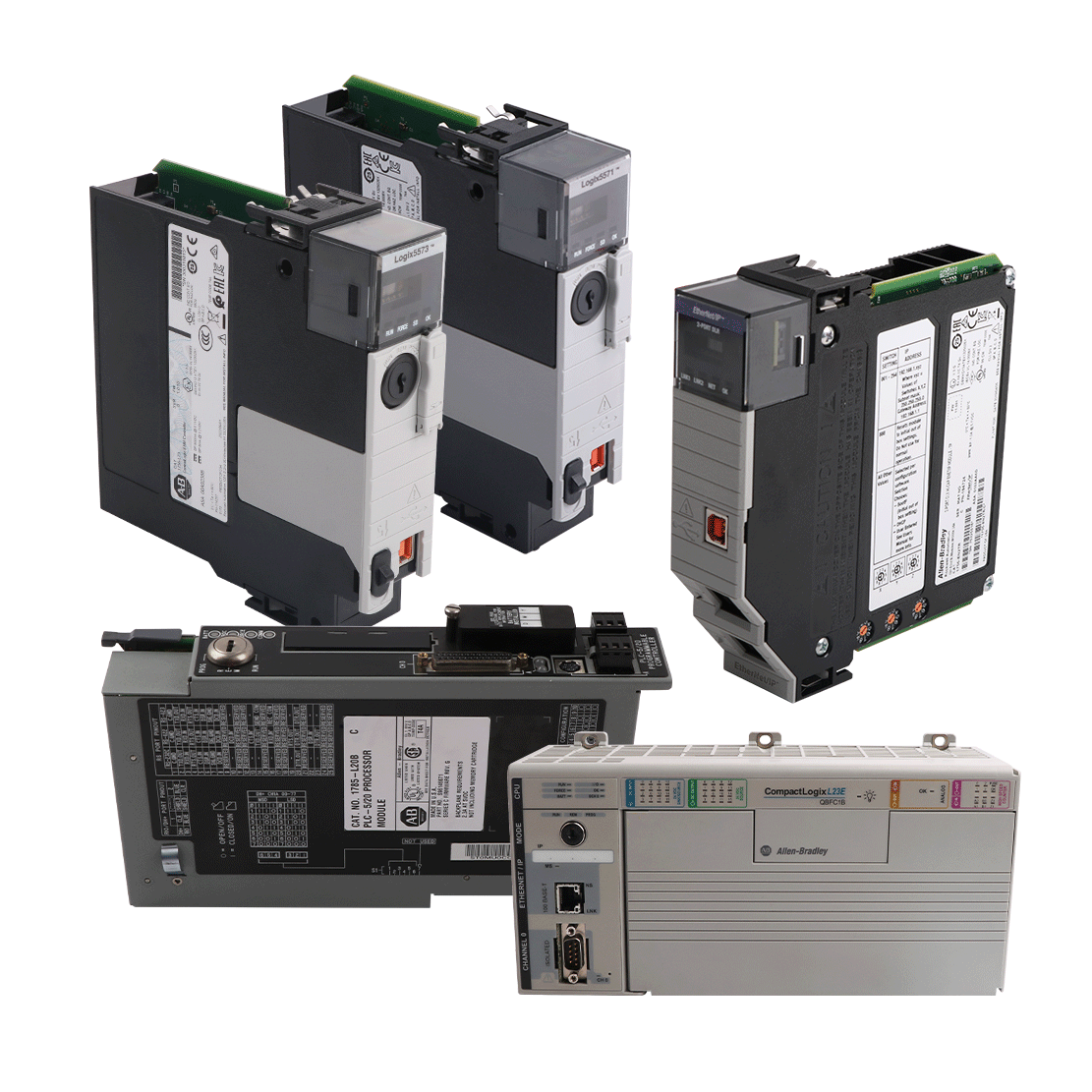

Understanding ABB VFDs

ABB VFDs are sophisticated devices designed to control the speed and torque of electric motors by varying the frequency and voltage of the power supplied. These drives find applications across a multitude of industries, from manufacturing and water treatment to HVAC and conveyor systems. The benefits of using ABB VFDs extend beyond just motor control; they also contribute to significant energy savings, reduced wear and tear on equipment, and enhanced operational flexibility. For instance, a friend of mine who manages a manufacturing facility shared how implementing ABB VFDs in their production line led to a 20% reduction in energy costs while improving their production rates. Such real-world applications highlight the value that ABB VFDs can bring to industrial operations.

Key Factors to Consider When Choosing ABB VFD Suppliers

When embarking on the journey to select the best suppliers for ABB VFDs, there are several essential criteria to keep in mind. First and foremost, product quality should be a top priority; ensure that the supplier offers genuine ABB products that meet industry standards. Customer service is another critical aspect; suppliers who are responsive and knowledgeable can make a significant difference in your purchasing experience. Technical support is vital as well, especially during installation and troubleshooting. Lastly, consider the availability of replacement parts—having a reliable source for components can minimize downtime in case of failures. A colleague once recounted their struggle with a supplier who couldn't provide timely support, leading to production delays that could have easily been avoided with a more responsive partner.

Comparing ABB VFD Suppliers

Comparing different suppliers of ABB VFDs requires a systematic approach to assess their offerings. Start by analyzing their reputation in the market; established suppliers often have proven track records and satisfied customers. Check online customer reviews, testimonials, and case studies to gauge the experiences of others. Additionally, evaluate their market presence—suppliers with a strong foothold in the industry often have better resources and support networks. When reaching out for quotes, prepare a list of questions that cover pricing, lead times, and warranty options. My friend, who recently purchased VFDs for his facility, emphasized the importance of clear communication; he found that suppliers who provided detailed responses were generally more reliable and trustworthy.

Additional Resources and Support

Choosing the right supplier goes beyond just the product itself; it's also about the additional resources and support they provide. Consider whether the supplier offers training for your team, installation services, and ongoing support—these factors can significantly influence the overall value of your purchase. Proper training ensures that your staff can operate the VFDs effectively, while installation services can save time and reduce the likelihood of errors. Ongoing support is crucial for addressing any issues that may arise post-installation. A personal anecdote from a friend highlights this; after purchasing VFDs from a supplier who provided excellent training and support, his team felt confident in their ability to troubleshoot minor issues, which ultimately led to smoother operations.

Key Takeaways for Selecting ABB VFD Suppliers

In conclusion, selecting the right supplier for ABB VFDs is a multi-faceted process that requires careful consideration of various factors. From understanding the functionality of ABB VFDs to evaluating supplier reputation and support services, every aspect plays a vital role in making an informed decision. As you navigate through your options, remember the importance of thorough research and evaluation. By applying the insights shared in this article, you can find a supplier that not only meets your needs but also contributes to the success of your operations.

Comments