Unlocking the Secrets of IS200VCRCH1B: Your Guide to Its Specs and Uses!

The IS200VCRCH1B component plays a pivotal role in various industrial applications, acting as a vital part of control systems that ensure efficient operations. Understanding its functionality and specifications is essential for engineers and technicians alike. This article aims to delve into the intricacies of the IS200VCRCH1B, shedding light on its design, operational parameters, and diverse applications. Whether you are a seasoned professional or a novice in the field, you'll find valuable insights that will enhance your comprehension of this crucial component.

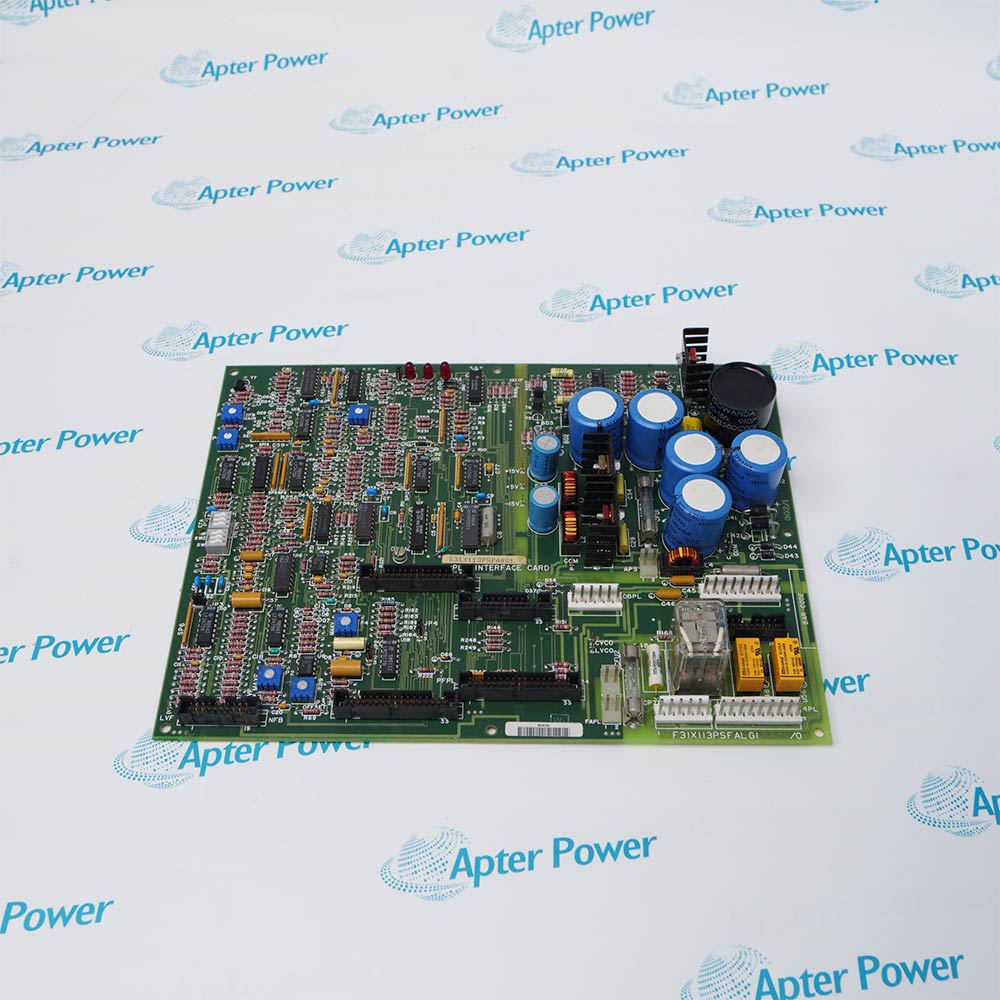

Understanding the IS200VCRCH1B Component

The IS200VCRCH1B is a type of circuit board that integrates seamlessly into various control systems, primarily used in industrial environments. Its primary function is to manage and regulate processes by receiving input from sensors and sending output signals to actuators. Designed with advanced technology, the IS200VCRCH1B ensures high reliability and precision in operations, making it indispensable in systems that require real-time control. The component's architecture typically includes microcontrollers, signal processing units, and communication interfaces, enabling it to handle complex tasks efficiently. In my experience, a colleague once shared a story about how a malfunctioning IS200VCRCH1B in a power plant led to unexpected downtimes, underscoring the importance of regular checks and maintenance for this critical component.

Specifications of IS200VCRCH1B

The specifications of the IS200VCRCH1B are key to understanding its capabilities and limitations. This component typically operates within a voltage range of 24V to 48V DC, with a current rating that can vary depending on the specific application. Its physical dimensions usually fall within standard sizes, making it compatible with various mounting systems. The IS200VCRCH1B also features multiple input and output channels, allowing for versatile integration into complex systems. Additionally, it is designed to withstand a wide range of temperatures, making it suitable for use in harsh industrial environments. The operational parameters include response times that ensure minimal lag in control actions, which is critical in time-sensitive applications. Understanding these specifications can help engineers select the right component for their specific needs.

Applications of IS200VCRCH1B

The IS200VCRCH1B finds its place in numerous industries, showcasing its versatility and effectiveness. In the energy sector, it is commonly used in power generation plants to monitor and control turbine operations, ensuring optimal performance and safety. In manufacturing, the component plays a crucial role in automation processes, where it controls machinery and assembly lines, improving efficiency and reducing human error. Furthermore, the IS200VCRCH1B is also utilized in HVAC systems, where it regulates temperature and airflow, contributing to energy savings and comfort. One notable application I heard about from a friend involved the IS200VCRCH1B in a large-scale water treatment facility, where it helped streamline operations and reduce waste, demonstrating its significant impact on environmental sustainability.

Maintenance and Troubleshooting Tips

To ensure the longevity and reliability of the IS200VCRCH1B, it is essential to implement routine maintenance practices. Regular inspections can help identify any potential issues before they escalate, including checking connections, cleaning dust, and securing signal supply. Additionally, examining the component for any signs of wear or damage is crucial to prevent erratic behavior. In some cases, users may need to reprogram or troubleshoot software-related issues to resolve unexpected performance issues. By adhering to these practices, the lifespan of the IS200VCRCH1B can be significantly extended.

Key Takeaways on IS200VCRCH1B

In summary, the IS200VCRCH1B is a crucial component in various industrial applications, known for its versatility and reliability. Understanding its specifications, functionality, and maintenance needs is vital for anyone working with control systems. As industries continue to evolve, the importance of such components will only increase, making it essential to keep abreast of advancements and best practices. I encourage readers to explore further into the world of industrial components, as this knowledge can lead to improved efficiency and innovation in their respective fields.

Comments