Unlock the Secrets to Finding the Perfect VFD Vendor: What You Need to Know!

Variable Frequency Drives (VFDs) are crucial components in modern industrial applications, enabling precise control over motor speed and torque. Their ability to optimize energy consumption and enhance operational efficiency makes them indispensable across various sectors, including manufacturing, HVAC, and renewable energy. However, the effectiveness of a VFD significantly depends on the quality of the vendor supplying it. Choosing a reliable VFD for sale is essential to ensure optimal performance, longevity, and overall satisfaction with the product. In this article, we will explore how to navigate the market for VFDs and assess potential vendors or manufacturers, setting you on the right path to making an informed decision.

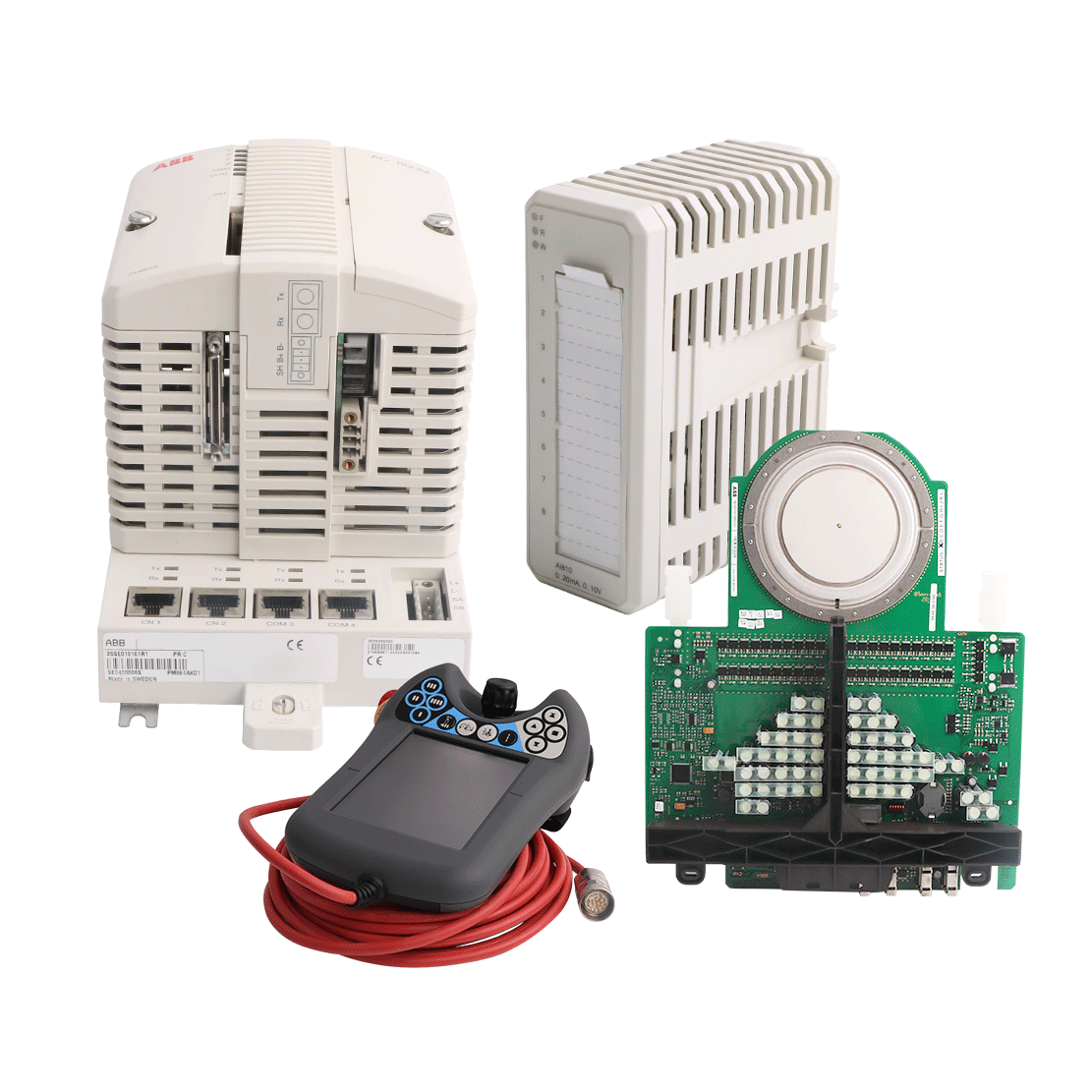

Understanding VFDs and Their Applications

VFDs function by controlling the frequency and voltage supplied to electric motors, allowing for smooth acceleration and deceleration, which reduces mechanical stress on equipment. This technology not only enhances the lifespan of motors but also leads to significant energy savings. In manufacturing, VFDs are used to manage conveyor systems, pumps, and fans, adapting their speed to meet varying load demands. In HVAC systems, they help modulate fan speeds, ensuring optimal temperature control while minimizing energy wastage. Additionally, in renewable energy sectors, such as wind and solar, VFDs assist in maximizing efficiency by adjusting the motor output to match changing environmental conditions. The benefits of using VFDs are clear: reduced energy costs, improved process control, and enhanced equipment longevity.

Key Factors to Consider When Choosing a VFD Vendor

When searching for a VFD vendor, several critical factors should guide your decision-making process. Firstly, consider the vendor's experience and track record in the industry. A vendor with years of expertise is more likely to understand your specific needs and provide reliable solutions. Reputation is also paramount; look for vendors with positive feedback and a solid presence in the market. Technical support is another crucial aspect—ensure that the vendor offers comprehensive support and training to help you maximize the use of your VFD. Moreover, check for vendor certifications and compliance with industry standards, as these can be indicators of product quality and reliability. A friend in the engineering field once shared how choosing a certified vendor saved his company from significant downtime due to a faulty VFD, emphasizing the importance of these factors.

Researching Potential VFD Vendors

Thorough research is vital when evaluating potential VFD vendors. Start by utilizing online resources, such as industry-specific websites, to gather information on various manufacturers. Industry forums can also be invaluable for gaining insights and recommendations from professionals who have firsthand experience with different vendors. Networking with peers in your industry can yield personal recommendations that might not be found online. Additionally, reading reviews and testimonials from other customers can provide a clearer picture of a vendor's reliability and customer service quality. One of my colleagues once recounted how he found a vendor through a forum discussion, leading to a successful partnership that improved his project's efficiency significantly.

Evaluating Vendor Proposals and Offerings

Once you have shortlisted potential vendors, the next step is to evaluate their proposals and offerings. Begin by comparing the features of their VFDs, focusing on aspects such as energy efficiency, control capabilities, and compatibility with existing systems. Warranties and support services should also be scrutinized; a good warranty can provide peace of mind regarding the product's longevity. Don't hesitate to ask questions to clarify any uncertainties you may have about the products or services offered. Engaging in open dialogue with vendors can reveal their commitment to customer satisfaction and willingness to assist. A friend shared his experience of asking detailed questions during a vendor meeting, which led to uncovering additional features that perfectly matched his project requirements, ultimately influencing his decision.

Choosing the Right VFD Vendor for Optimal Performance

In conclusion, finding the right VFD vendor requires careful consideration and thorough research. Understanding the importance of VFDs and their applications, evaluating key vendor factors, and engaging in detailed research can significantly impact your final decision. The insights shared in this article underscore the need for diligence and patience in selecting a vendor that aligns with your specific needs. By taking the time to assess your options, you can ensure optimal VFD performance, reliability, and satisfaction in your projects. Make informed choices and reap the benefits of effective motor control solutions.

Comments