3D printing is being used to solve some of the most difficult problems

Body

As an engineer, you're constantly looking for ways to mitigate challenges in the manufacturing industry – a world that is by nature complex. These 3D printing technologies are still in their infancy when compared to how long manufacturing has been around. As a result, not everyone is aware of the benefits and problems that can be solved by using them.

It takes time to produce high-quality products. Furthermore, with traditional manufacturing methods, waiting periods ranging from several weeks to several months for parts were standard.

Here's how it's done:By utilizing additive technologies, it is possible to eliminate the need for tooling, which can be both costly and time-consuming. Labor costs are being reduced as a result of largely automated processes and technology. Moreover, while significant cost savings of this magnitude are rare, technological and material advancements may make figures like these more common in the future.

Because additive manufacturing does not necessitate the use of molds or tooling, the risks associated with potential mistakes are reduced to a significant extent. Comparing 3d printing to traditional manufacturing processes, making changes on the fly is significantly more feasible and significantly less expensive. When it comes to 3D printing parts, there is a level of added convenience that older methods simply cannot match.

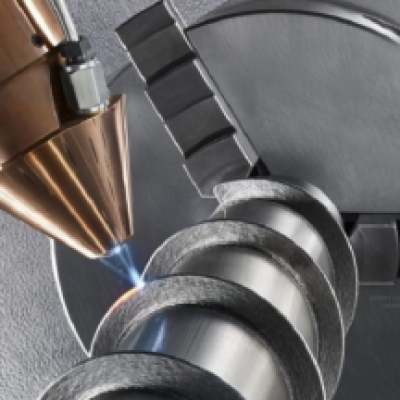

One of the most compelling aspects of additive manufacturing is the level of complexity that can be achieved when fabricating parts in a controlled environment. As a result of the lack of many of the constraints associated with traditional manufacturing, issues such as draft angles and tool access are not required to be taken into consideration. Engineers now have a great deal more flexibility in their designs, allowing them to create designs that were previously too complex to be practical.

Certain custom 3D printing processes (such as HP's Multi Jet Fusion) are helping to pave the way for more environmentally friendly manufacturing by using reusable PA 11/PA 12 powders and employing processes that are generally less wasteful. In this vein,If advances in custom 3D printing technologies continue in this vein, they will eventually bring the manufacturing industry to a point where it is universally regarded as being viable for the long term. In the meantime, reducing the environmental impact of manufacturing is a significant challenge that must be overcome, and 3D Printing Services is unquestionably a step in the right direction.

Therefore, a significant amount of storage space is required to house goods that can remain on the shelf for months or even years at a time. This comes at a high financial cost. In the manufacturing industry, the use of 3D printing parts has the potential to lower costs by reducing the amount of storage space required.{anchor} makes it possible to manufacture goods in the same location where they are sold. Overproduction and increased storage costs are avoided as a result of this arrangement.

Comments