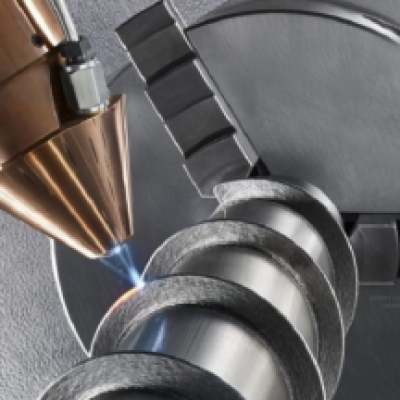

CNC equipment used in the production of superalloys

الجسم

Today's cnc machining service device manufacturing industry has access to some of the most efficient and accurate tools available. Precision CNC machining is one of those tools. Even the most difficult medical components and assemblies to design and manufacture can benefit from this technology, which can provide cost-effective solutions for them. There are several aspects of 5 Axis CNC Machining Services that are particularly advantageous, including its ability to produce components with exceptional accuracy while also being compatible with an extensive range of materials such as plastics, metals, and specialized materials. Our capabilities range from CNC Swiss Micro Machining to Laser Welding and Wire EDM, to name a few areas of expertise. Today's topic will be some of the most innovative Swiss CNC Machining applications for medical devices, which will be discussed in detail.

Computer-aided design (CAD) files are no longer required because CNC machines today enable a powerful digital manufacturing process that produces strong, highly accurate parts directly from a CAD file. CNC technology allows for the production of high-quality medical devices, tools, and components. It is possible to use this high-precision machining technique to create high-quality surgical and dental devices, which will allow for the provision of patients with faster and more dependable patient care. Minimally invasive surgeries today necessitate the use of components that are extremely small and precise, which must be machined. The use of smaller devices and tools can assist patients in experiencing less pain and trauma, which will allow them to recover more quickly in the long run. With CNC Micro Swiss machining, it is possible to produce these high-precision parts in a timely and cost-efficient manner.

CNC Micro Swiss machines are designed for the production of extremely precise parts of exceptional quality, with computer numerical control as the primary means of production. Components used in the manufacture of CNC Medical Machining tubes must adhere to extremely strict tolerance requirements, which are even more stringent when it comes to high-quality production runs. For the purpose of better serving the medical device communities that we serve, we have introduced CNC laser tube cutting to our operations. By employing this technique, you can cut tubes with diameters up to.315 inches and lengths up to 40 feet in a short amount of time while maintaining high accuracy and repeatability.

When using a CNC laser to cut tubes, a small heat-affected zone (HAZ) is created. A heat-affected zone (HAZ) refers to the area of a tube that is affected by the laser's heat without melting. Using CNC laser cutting, you can produce Precision CNC Machining tube components with tight tolerances while maintaining component strength and cost efficiency.

A cutting-edge technology known as Electrical Discharge Machining (EDM) allows for the production of many different components, including very small parts for medical devices, in a single operation. While the work piece is submerged in deionized water, a metal wire that has been electrically charged is used to cut through it. The deionized water cools the cut and removes any debris that may have accumulated in the wound as a result of the wire's extreme precision in eroding conductive material.

Using CNC wire EDM, you can create complex shapes from conductive materials that range from hard metals (such as titanium and tungsten carbide) to softer materials (such as aluminum or exotic alloys), and everything in between. A fragile portion of a small component that was otherwise unusable was made usable by using CNC Wire EDM at Marshall to create highly accurate machine features, such as slots or eyelets, in a fragile portion. A variety of tasks, such as the creation of grooves, slots, and holes, can be accomplished through the use of EDM technology.

تعليقات