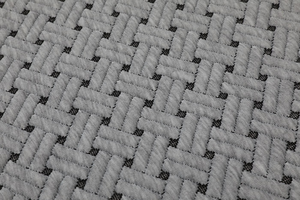

Precautions for knitted fabrics in production

الجسم

In order to produce a good quality knitted mattress fabric ,the production process of the knitted fabric must be strictly observed. Today, we will explain the precautions in the production of knitted fabrics!

1.The knitted cloth will be plugged in the net when printing

Knitted fabrics are a headache because of the large number of grey fabrics. The main reason is that the knitted fabrics are not singeed and mercerized because of the different pre-treatment processes of knitted fabrics and woven fabrics. It is easy to fluff when handling cloth, so this phenomenon occurs when printing.

Solution:

1) The warehouse should strengthen the inspection of the grey cloth. For the knitted fabric with poor quality, the warehouse must inform the customer in time, communicate with them to explain the reasons, and give the treatment method.

2) Adjust the process of knitting cloth in time. And increase the number of washings, try to reduce the hair to a minimum; 3, in the semi-finished products, increase the flow of water in the groove, let the flowing water wash away a part of the hair.

- 2. There are more holes in the finished knitted fabric

The holes in the finished knitted fabric are mainly caused by the following reasons: there are holes in the body; mechanical damage causes holes; human causes cause holes.

Solution:

1) Carefully inspect the grey fabric with many neps, yarn breakage or yarn joints, and notify the customer to deal with it in time.

2) Choose a smooth and good performance cylinder to handle the knitted fabric.

The problem of weight in the production of knitted fabrics

In general, customers pay more attention to the weight of knitted fabrics, and it is also an important part of the quality of knitted fabrics.

In order to ensure the weight of each batch of knitted fabric, the measures to be taken are as follows:

1) To check the quality of the fabric, generally the weight of the blank can reach the weight requirement of the finished product, but if the weight of the semi-finished fabric does not reach the weight of the finished product Requirements, then the finished product is difficult to meet the requirements of weight;

2) Machine equipment, process operation, reasonable choice of dyeing chemicals.

- The problem of anti-staining of knitted fabrics in washing

Since the knitted fabric has not been mercerized, it is more likely to be stained during the washing process, so the anti-staining requirement is also higher.

Therefore, we must do:

1) Steaming hair color should be complete. If the steaming is not good, the water color will be heavy, and the stain will be more powerful.

2) The floating color should be cleaned. Less floating color, it is not easy to be stained when soaping.

3) Wash with a soaping agent with better anti-staining properties to avoid staining.

If you want to learn more about the craft, click here:woven mattress fabric .

تعليقات