characteristics of CNC machining is the presence of a mechanical component

Body

While CNC programming is a lesser-known profession than others such as web development or application programming for mobile devices, it is still highly valued and well-paid in comparison to these other fields. Anyone who has worked in the field of CNC programming will tell you that it takes a significant amount of time to gain valuable experience in this field. All that remains to be determined is which type of experience is more beneficial.

Once they become familiar with the language and its syntax, traditionally trained programmers are unlikely to encounter any difficulties in learning G-code. It is only necessary to have a fundamental understanding of standard G-code commands, their relevant parameters, and how they translate into real-world tool and machine movement. This programming language, in contrast to other programming languages, does not typically rely on the use of loops, does not include complex logical functions, and does not even have a mechanism for declaring the values of variables.

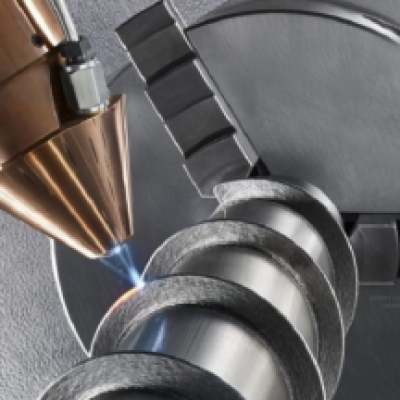

A good example of the critical role that hands-on machine shop experience plays in developing the skills required for CNC milling is shown in the figure below:No matter what level of G-code programming experience a machinist has, they will be able to discover new and more effective ways of using a CNC machine and maximizing its capabilities, regardless of their previous experience with CNC machines. The difficulty of G-code programming should never be underestimated; it is a skill that takes years to master and can take several years to achieve complete mastery of.

With time, computer numerical control (CNC) machining will become more widely used in modern manufacturing practices, and this is a technology that will only become more widely used. This information makes it simple to envision a long-term and financially rewarding professional career as a highly skilled CNC machinist or programmer in light of the information provided above. For those who want to learn a skill that will prepare them for a well-paying job, CNC prototyping is an area they should consider furthering their investigation into further.

Overall, becoming proficient in requires two components: a thorough understanding of how the machines work, and a thorough understanding of how the G-code programming program works. It is unquestionably more valuable to gain hands-on experience in a machine shop rather than traditional classroom education in the vast majority of cases. For the contrary, learning to use CNC machines takes years of practical experience with the machines as well as delving deeply into the code (as well as hundreds of mistakes along the way).

Do you have faith in your ability to learn CNC on your own timetable?

Learning the fundamentals of CNC programming is a straightforward process if you understand the fundamentals of mathematics and have a fundamental understanding of how machining works. Generally speaking, this is something that can be learned in a couple of days or even less time in the vast majority of cases. In a year, it is possible to learn intermediate CNC programming skills; however, learning and mastering advanced CNC programming skills will take several years of practice and repetition on a computer.

Is it possible to learn CNC programming from the comfort of one's own home, based on the information presented here?

It is highly recommended that you take this course if you are interested in learning CNC Programming (computer numerical control). It is also available to view on the internet. In order to complete the course, you will be provided with a self-guided video course, a printable workbook, and exercises that are simple to complete. The National Institute of Management Certification Examination is a fantastic preparation tool for the National Institute of Management.

Are computer numerical control (CNC) manufacturing techniques difficult to grasp? Is it difficult to gain an understanding of these techniques?

Consider your options before embarking on a career in CNC milling part.

A career in computer numerical control (CNC) machining is the best one you've never heard of before. It involves using computers to control machines. It entails the use of computers to control mechanical devices. This industry, in addition to being well-compensated and offering excellent long-term employment prospects, offers a diverse range of interesting job opportunities. A college degree is also not required to get started in this field, and you can get started right away without one. In light of our findings, we believe that more job seekers should seriously consider a career in the skilled trades, and we encourage them to pursue this option.

First and foremost, is pursuing a career as a CNC programmer a wise decision?

At the moment, CNC machine-tool programming (also known as computer numerical control) is one of the most sought-after careers in the advanced manufacturing industry. According to the most recent data, Senior CNC Programmer Jobs in Los Angeles pay an average of $85,960 per year, which is higher than the average salary for the industry, which is $76,000 per year. Senior CNC Programmer Jobs in other cities pay an average of $85,960 per year.

The hourly wage of a CNC programmer is determined by the amount of experience the programmer has.

Machine tool programmers earn salaries ranging from $32,330 to $75,780 per year in the United States of America, with a median salary of $48,990, according to data from the Bureau of Labor Statistics. CNC programmers are responsible for programming CNC machines. CNC Programmers earn an annual salary that ranges from $48,990 to $57,000 on average, with the top 80% earning an average salary of $75,780 per year in the general population.

Globally, the G-code programming language (also known as RS-274 or RS-274) is the most widely used computer numerical control (CNC) programming language, accounting for nearly half of all CNC programming languages used in manufacturing and manufacturing automation. Automated machine tools are controlled by computer-aided manufacturing systems, which is a term that refers to the use of computer-aided manufacturing systems to control automated machine tools. This type of system is available in a number of different configurations.

Comments