Why do castings made of magnesium alloy have such an incredibly high level of quality compared to other types of casting

Cuerpo

In light of the fact that the various existing methods for processing appearance still have their own issues, in order for us to accomplish this goal, we should first gain an understanding of the primary challenges presented by the various processing skills. This will allow us to make progress toward our objective. Because of this, we will be able to make progress toward the goal that we have set.

1. The specific weight of a lightweight magnesium alloy is comparable to 68 percent of the weight of aluminum alloy, 27% of the weight of zinc alloy, and 23% of the weight of steel. In addition, magnesium alloys are suitable for use in the manufacturing of a variety of different products.

Plastics are frequently used in the construction of lightweight computer housings; however, these plastics do not support electromagnetic shielding. Plastics are commonly used in the construction of lightweight computer housings. For the electromagnetic radiation shielding to fulfill the requirements that have been established, either the plastics need to be reworked or they need to be painted. Neither option is acceptable. Excellent thermal conductivity and thermal spread are associated with having a power consumption in a laptop that is typically between 20 and 30 watts. This range of power consumption die casting products is typical. As a direct consequence of this, it is absolutely necessary to take into consideration heat conduction as an element of the overall stability of the system.

As a direct result of this, it is absolutely necessary to take measures to prevent the central processing unit, also referred to as the CPU, from becoming excessively hot in order to take measures to prevent the temperature of the computer as a whole from becoming excessive. When developing a brand-new laptop, the engineers will frequently decide to incorporate heat pipes and fans into the design in order to make certain that the system is able to maintain a stable temperature. Recent findings from testing suggest that the use of magnesium alloys may be able to lessen the severity of problems caused by overheating. Needs additional citations.

2. It is absolutely essential to keep in mind that even though it is noticeably stronger and more rigid than steel, it is also a lot lighter than steel. This fact is true despite the fact that it is significantly lighter than steel. This is not something that can be disregarded in any way.2 magnesium alloy case is dropped from a height of one meter and the magnesium alloy case continues to function properly after the fall, then the magnesium alloy case weighs five pounds and is indestructible. If the magnesium alloy case continues to function properly after the fall, then the magnesium alloy case is indestructible. In addition to this, the magnesium alloys have a higher resistance to corrosion than the aluminum alloys. Both the metallic sheen and the metallic texture have been present in people ever since the turn of the previous century; neither of these qualities should be eradicated. Metallic sheen and metallic texture have been present in people ever since the turn of the previous century.

The fact that magnesium alloy silicon alloy has a pleasing appearance and texture is something that industrial designers are unable to ignore because the material is made of metal. This is something that prevents industrial designers from using magnesium alloy silicon alloy in their designs. This is due to the composition of magnesium alloy silicon alloy, which is a metal.

5. A laptop case made of plastic should have a greater thickness (greater than 2 millimeters), as recommended by Cost, in order to maintain its strength. The designers had no choice but to keep adding more metal in order to protect the internal components and ensure the stability of the plastic frame; otherwise, they would not have been able to support the plastic frame. This was necessary in order for them to be able to support the plastic frame.35 and 1 millimeters in thickness, and the finish can be painted or plated, whichever you prefer, depending on your personal preference. Even though we have professional production management, which ensures that we do not fill screws, do not support stainless steel, and do not use conductive paint, the price may be higher than that of plastic in die casting certain circumstances. This is because we do not fill screws, we do not support stainless steel, and we do not use conductive paint. In spite of this, the price may end up being significantly more than that of plastic. Plastic products that were designed to have a minimal impact on the natural world have reached the end of their service lives; the majority of these products cannot be recycled, and they will continue to be garbage and waste for the next one million years. Plastic products that were designed to have a minimal impact on the natural world have reached the end of their service lives. Recycling plants will get rid of the products that have been used up to a certain point once the industry has developed to the point where they are no longer needed.

This will happen once the industry has reached the point where they are no longer needed. Because of this, there are a variety of advantages that are produced for end users as a direct result of the utilization of magnesium alloys. These advantages can be categorized as either health-related or financial in nature.54 millimeters, which enables them to be used in the construction of extremely thin aesthetic designs and makes them suitable for use. 54 millimeters, which enables them to be used in the construction of extremely thin aesthetic designs.54 millimeters, which enables them to be utilized in the construction of extremely thin aesthetic designs. Citation neededThe thickness of ultra-thin materials ranges somewhere between 0 and 100 nanometers on average. Plastic is notoriously difficult to work with, and the light shell that is made of aluminum alloy has a thickness that is greater than 2 millimeters. When it comes to achieving this level of thinness, plastic is notoriously difficult to work with. As a consequence of this, magnesium alloys are easily capable of keeping a uniform shell thickness of 2 millimeters throughout the entirety of the structure. Cause and effect

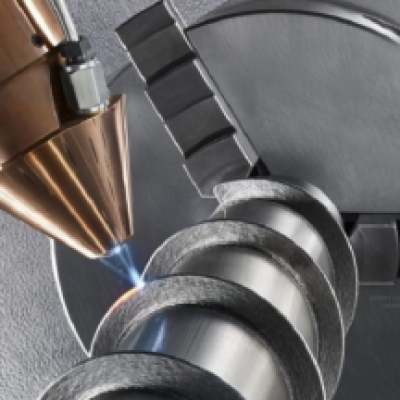

Because of the expansion of industry and the rise in overall productivity, magnesium alloys are gaining a stronger foothold in markets CNC machining all over the world. This is a direct result of the growth that has been seen in overall productivity. In addition, a wide variety of design and appearance technologies have reached a point of maturity where they are now capable of being applied in a widespread manner and are now considered to be mature. This is an exciting development.

Applications in the field of electronics that do not produce flames take into account the possibility of combustion caused by engineering plastic.

Magnesium alloys have a higher melting point than plastics, making them significantly less flammable. This is because the melting point of magnesium alloys is 427 degrees Fahrenheit. Because the vast majority of magnesium's raw materials are extracted from seawater, the availability of magnesium will never be in short supply. This is due to the fact that the seawater is a reliable and abundant source of magnesium's raw materials, making it possible for there to be no magnesium shortage. Magnesium will never be in short supply for a number of reasons, and this is one of them.

Comentarios