Carbon Fiber vs. Traditional Materials: A Comparative Analysis

Cuerpo

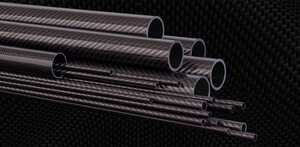

In today's technologically driven world, the demand for materials that offer both strength and flexibility is continuously increasing. While traditional materials have served us well for centuries, the emergence of carbon fiber presents an innovative alternative. Carbon fiber composites are made of carbon atoms. The lightweight, high-strength material is known for its exceptional mechanical properties. It is composed of thin strands of carbon atoms that are bonded together in a crystalline arrangement. These carbon atoms are aligned parallel to the long axis of the fiber, which gives carbon fiber its incredible strength and stiffness. This article delves into a comparison between carbon fiber and its traditional counterparts, highlighting the advantages and applications of each.

Application of Carbon Fiber Vs Traditional Materials

Traditionally, materials like wood, steel, and aluminum have been the backbone of various industries, from construction to automotive manufacturing. Their reliability, abundance, and familiarity made them the go-to choices for multiple applications. However, with the rise in technological advancements and the need for lightweight yet sturdy materials, carbon fiber has made a significant impact on the scene. It is widely used in industries such as aerospace, automotive, sports and leisure equipment, civil engineering, and more. It's used to make components such as aircraft wings, car bodies, bicycle frames, tennis rackets, and even in advanced medical devices. However, the production process can be expensive and energy-intensive, which can impact its cost and availability for certain applications.

Why Carbon Fiber has an advantage over traditional materials?

Strength and Weight: Metals like steel and aluminum have long been lauded for their strength, forming the skeletal structure of skyscrapers, bridges, and cars. However, they come with significant weight. Carbon fiber offers a compelling argument here. It boasts an impressive strength-to-weight ratio, often delivering strength comparable to these metals but at a fraction of their weight. This attribute has been particularly beneficial in sectors like aerospace, where every ounce matters.

Adaptability in Design: The beauty of carbon fiber products lies not just in their strength but also in their versatility. Industries today require materials that can be molded into various shapes and sizes. Here, products like carbon fiber rods shine. They can be tailored to specific lengths and diameters, catering to unique needs, be it in the realms of sports equipment or architectural structures.

Resistance to Elements: While metals, especially iron, are prone to corrosion when exposed to moisture or specific chemicals, carbon fiber presents a robust front. Its resistance to corrosion makes it a durable choice for environments that are less forgiving, such as marine applications or automotive exteriors.

Thermal Stability: Traditional materials have a known Achilles' heel: they expand or contract considerably with temperature fluctuations. In contrast, the composite material exhibits minimal thermal expansion. This ensures that whether it's freezing cold or scorchingly hot, products, especially long carbon fiber tubes, sheets etc. remain stable, making them ideal for a range of applications.

Modern Aesthetics: The unique woven appearance doesn’t just indicate its strength; it also has an aesthetic appeal. This modern, sleek look makes it a favored material in the design of luxury items, from high-end automobiles to premium gadgets.

However, it’s crucial to note that every material has its domain where it performs best. While carbon fiber tubes might be optimal for crafting a lightweight bicycle frame, a steel beam would be more appropriate for supporting the weight of a skyscraper.

To wrap it up, traditional materials, with their rich history and proven reliability, will always be vital in manufacturing. However, with its unique properties and the vast array of carbon fiber products, is rapidly staking its claim. As technology propels us forward, the role of the composite in shaping the future of various industries becomes even more intriguing.

Explore all your carbon fiber composites needs with NitPro Composites. The reliable manufacturers have the technology of producing carbon fiber rods, tubes, sheets, pultruded profiles, CNC parts and more.

Source by- https://www.zupyak.com/p/3803189/t/carbon-fiber-vs-traditional-materials-a-comparative-analysis

Comentarios