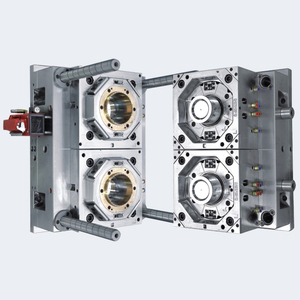

Common Mistake When Choosing Plastic Bucket Mould

الجسم

Selecting the right plastic injection molding machine- Plastic Bucket Mould is one of the most important criteria in making quality parts consistently and profitably. The right machine will help keep costs low and make you more competitive. This will allow you to sell more parts, earn more money and at the same time establish a reputation as a quality manufacturer.

Mistake 1 : Buying Used Injection Molding Machines That Don’t Work

The key to buying a reliable used machine is to find one that has been fully inspected and tested before delivery so that you won’t suffer loss of production due to multiple breakdowns.

Mistake 2: Selecting Large Screw Diameters.

Large screw diameters can cause quality problems due to material degradation. When small shot sizes are used with large screw diameters, the plastic material spends more time being heated by the barrel heaters compared to large shot sizes. Material degradation is more likely to occur if the shot size is small compared to the injections units maximum shot capacity especially for heat sensitive materials. Another problem with large screw diameters are the large shearing forces generated during screw rotation, this can also degrade the material and is likely to lead to reject parts.

Mistake 3: General Purpose Screws

The advantage of a general purpose screw is that they can be used with most plastic materials such as PP, PE, Nylon, PET and PC so they are very flexible and good for moulding companies that mould a variety of different materials.

Mistake 4: Injection Pressure Limited.

To consistently make quality parts the molding process must not be limited by the injection pressure. It is advisable to have at least 10% injection pressure in reserve so that the injection molding machine-Pail Mould can automatically adjust to normal variation in the plastic material viscosity.

تعليقات